Oxy-Fuel Burning & Plasma Cutting

LB Steel has state-of-the-art tables that can handle plate up to 270″ wide and 16″ thick. And all our tables are new or recently rebuilt. You won’t find another source for Oxy-Fuel or Plasma burning in the region that can match our capacity or quality.

Laser Cutting :

Laser cutting works by directing a high-power pulsed laser at a specific location on the material to be cut. The energy in the laser beam is absorbed into the surface of the material and the energy of the laser is converted into heat, which melts or vaporizes the material. Additionally, gas is focused or blown into the cutting region to expel or blow away the molten metal and vapor from the cutting path.

There are numerous advantages of laser cutting over mechanical cutting such as plasma cutting or turret punching. All of the following advantages result in dramatic cost savings.

Laser Cutting Advantages :

- High accuracy cuts with excellent repeatability

- Produces clean cutting edges which require minimal finishing

- Smaller cut taper than other methods

- Minimal heat input, low edge loads during cutting — less distortion

- No physical contact with the material — no metal contaminates can embed into the material

- Complex shapes, very intricate and difficult geometric cuts possible

- No expensive tooling to add to the cost

- No tooling makes prototyping parts inexpensive and fast

- Increased cutting speeds and higher throughout

- Cut several parts simultaneously

- Allows nesting of like materials and thicknesses together on the same plate

LB Steel has state-of-the-art tables that can handle plate up to ¾ thick

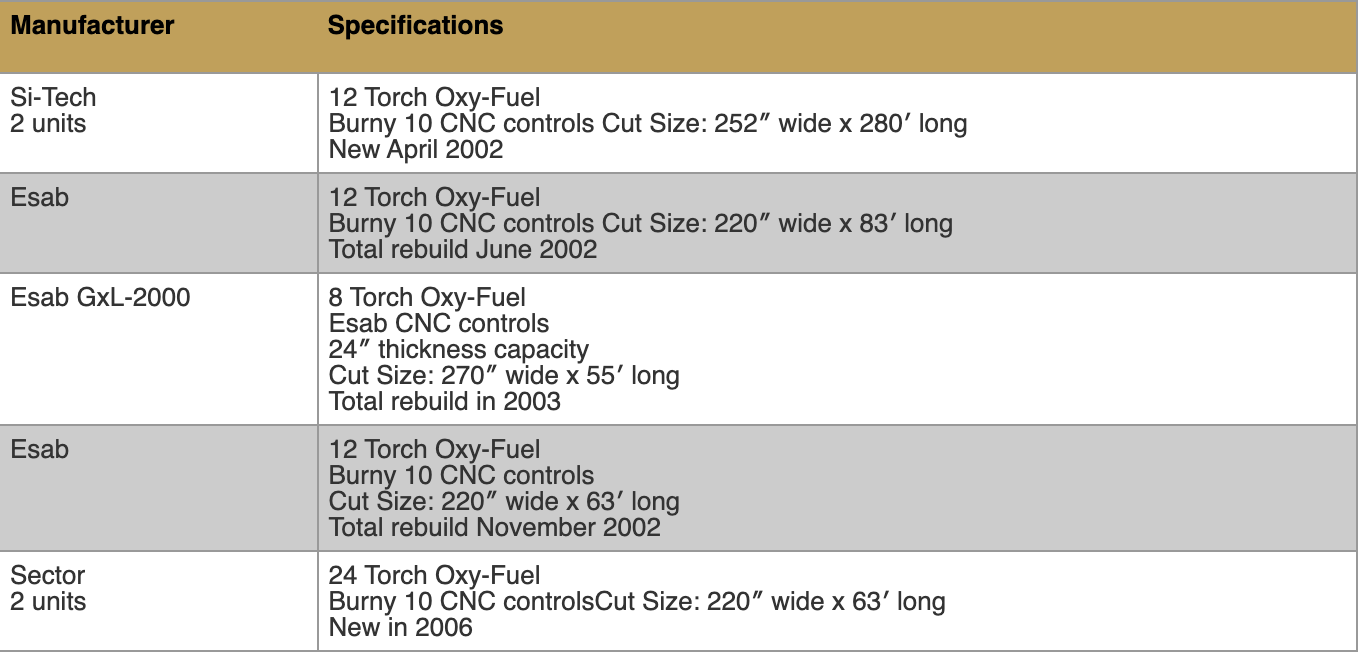

Oxy-Fuel Torch Tables:

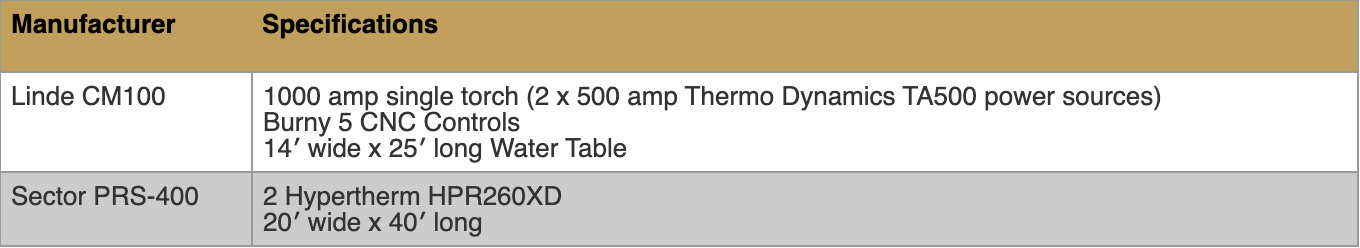

Plasma Tables:

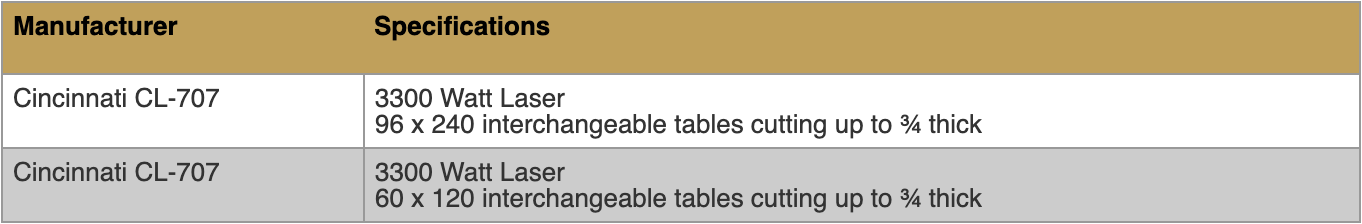

Laser Tables: