Fabrication & Welding

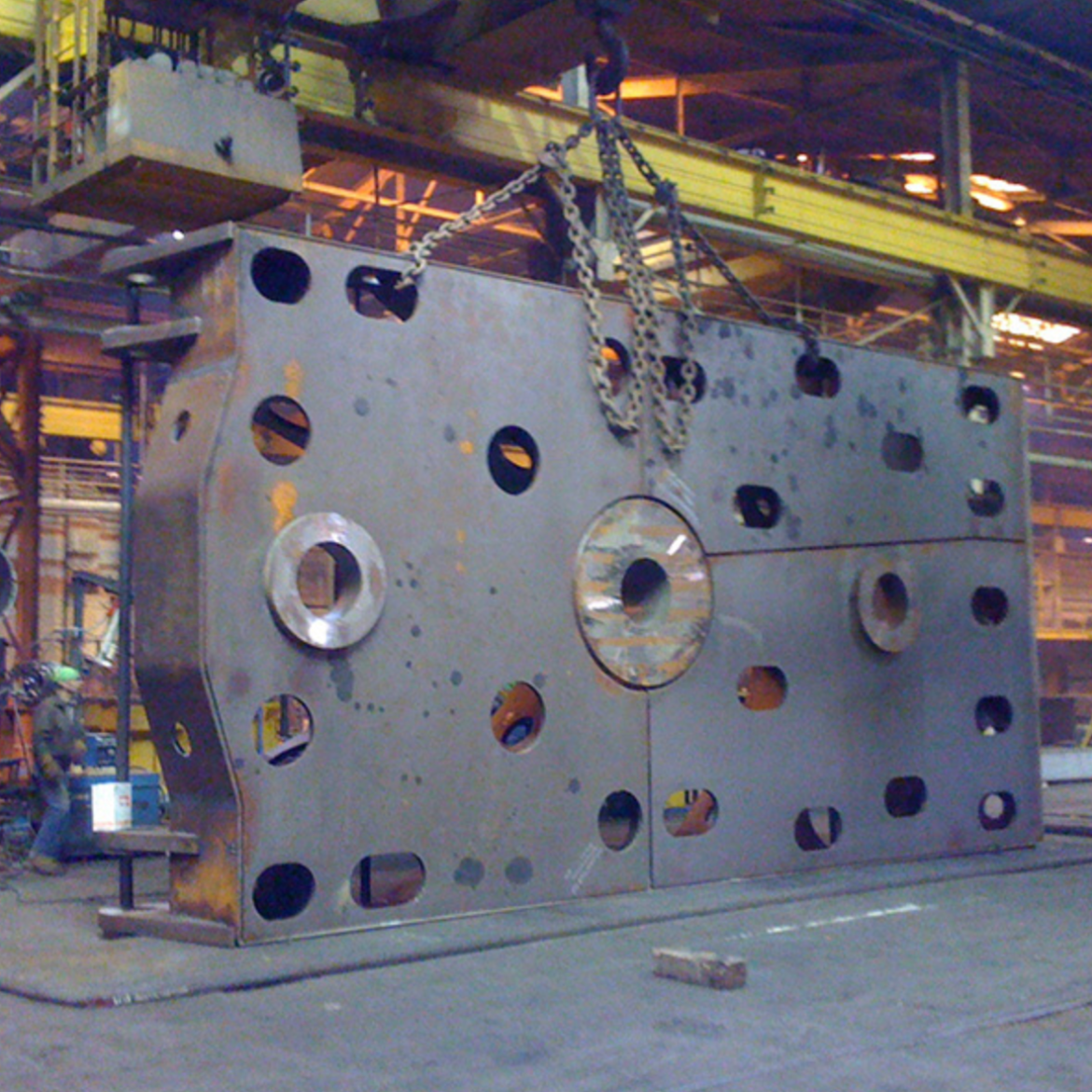

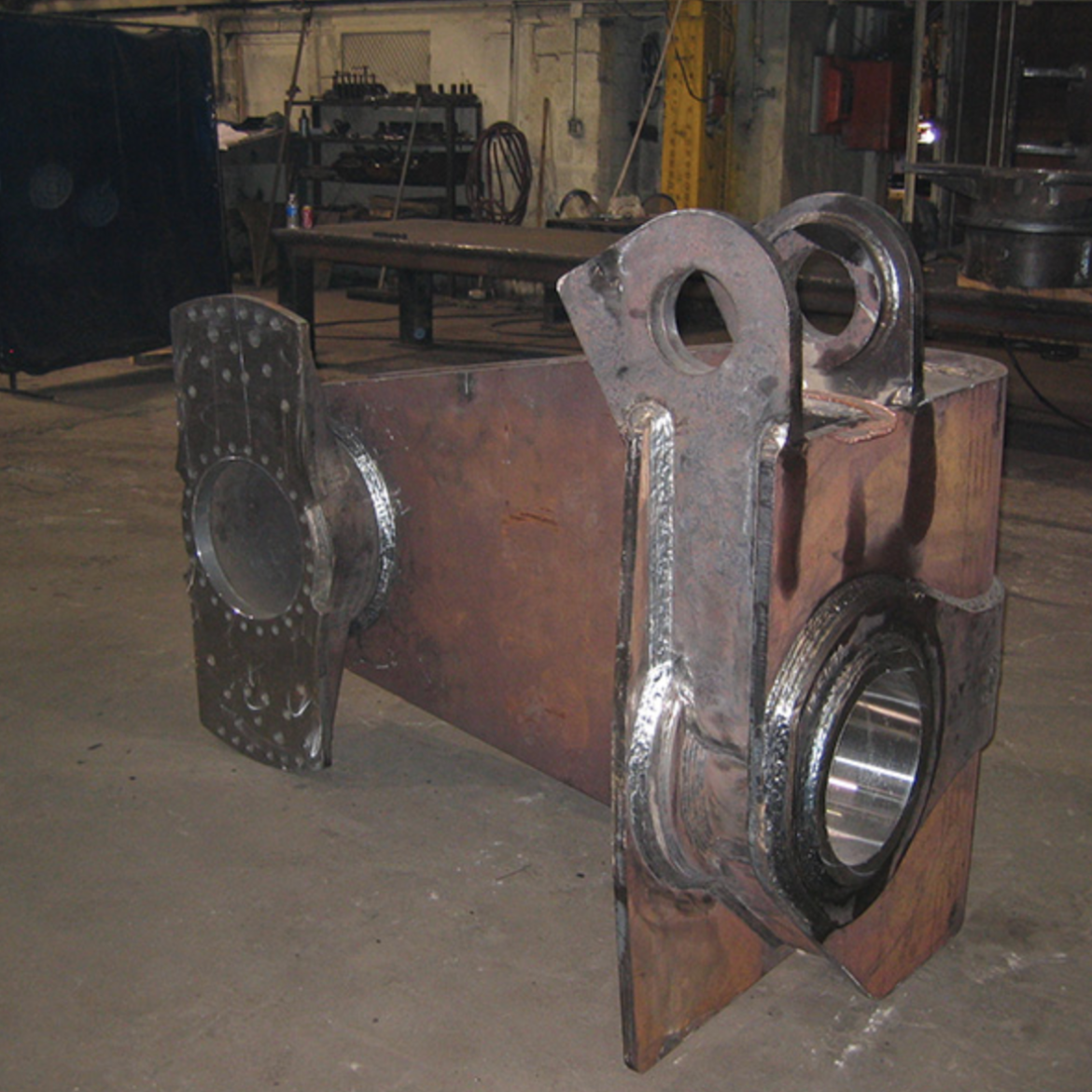

Fabrication

LB Steel’s versatile welding capabilities include both manual and multi-axis robotic welding work stations. Our welding specialists are trained and certified in-house in a variety of processes and standards to ensure the highest weld quality. Each specialist is certified to both industry and customer standards through rigorous testing. Certified process capabilities include FCAW, GMAW, SMAW, TIG and SAW. We employ 4 full-time CWI’s and 1 ASNT NDT Level III, qualified in LP, MP, RT and UT for your toughest inspection requirements.

Our library of fixturing and tooling, as well as design/build capabilities using CAD Modeling, ensures you have a consistent product each and every time. The fabrication cycle is controlled by using visually-aided process booklets that guide specialists through your most detailed and intricate weldment ensuring both cycle times and product consistency requirements are met.

Welding:

We offer a full range of value-added welding and fabricating services. Our wide range of material choices that match your application requirements (A6, Certified Chemistry Plate, and identified chemistry plate) allow us to maximize value and quality on your project.

EN 15085-2 Quality Control:

The EN 15085 standard series applies to the design, manufacturing, testing and conformity assessment of welded railway vehicles, components and assemblies. It sets requirements for the quality system, welding process approvals, as well as performance qualifications for welder and welding operator.

Coded Welding Capabilities:

- ASME Pressure Vessel

- U-Stamp Section VIII Division I

- R-Stamp Section VIII Division I: Repair Conformance

- U.S. Department of Energy: Comply AWS D-1.1 and D-1.5

- Bridge and Structure

Standard welding procedures including:

- Hot Rolled Plate, Aluminum, Stainless Alloy, etc.